Add to Cart

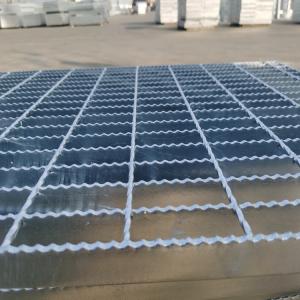

walkways metal grating mild steel aluminum bar grating with free samples

1. Steel Grating Type

1) Construction of Steel Grating : Forge- Welded Grating and Press- Lock Grating

2) Bearing Bar Type:

Flat Bar Grating; Serrated Bar Grating ; I Bar Grating (include flat bearing bar and serrated bearing bar)

2. Common Steel Grating Specification

1) Bearing bar size (mm): 25 x 3; 25 x 5;30 x 3; 30 x 5;32 x 3; 32 x 5; 35 x 3;35 x 5.....

2) Bearing bar pitch(mm): 20;30;34;40;50;60.....

3) Cross bar pitch(mm): 50;100;38.....

3. Grating Standard

YT/T 4001.1-2007; BS4592-1:1995; AMSI/NAAMM(MBG531-2000); AS1657-1992

| Material Standard | ASTM A36, A1011, A569, Q235, S275JR,Stainless steel 304, Mild steel & Low carbon steel, etc |

| Bearing Bar (width*thickness) | 25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10…..100 x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1''x3/16'', 1 1/4''x3/16'', 1 1/2''x3/16'', 1''x1/4'',1 1/4''x1/4'', 1 1/2''x1/4'', 1''x1/8'', 1 1/4''x1/8'', 1 1/2''x1/8'' etc |

| Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3,32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc. US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

| Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

| Surface treatment | untreated(black), hot-dipped galvanized ,powder coated, electroplate, painting or as per customers’ requirement. |

| Grating Style | Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

| Packing | 1) LCL(less than one container load): packed with plastic film then on the pallets 2) FCL(full container load): nude packing 3) Other special package :according to customers' requirements. |

| Payment Term | T/T,L/C, Paypal, Western Union, MoneyGram, Credit Card ,D/A,D/P, Trade assurance |

INSTALLATION OF STEEL GRATING

1. There are two ways of installation for grating. One way is by welding and other is by using installation fastener. The welding method is suitable for those parts which will be fixed forever,such as platforms for equipments,while the method by using installation fastener has the properties of easy to assemble and disassemble and of preventing destroying the zinc layer.

2. Installation fastener is suitable for all types of gratings. It is made of up-fastener,down-fastener and inside cylinder bolt M10.

3. Welding method is angle welding at the first bearing bar of every corners on the grating.Welding seam of which is not less than 20mm length and not less than 3mm height.

4. It at least needs four sets of installation fasteners on every grating to fix.You had better install more fasteners on the supportable construction when the span is larger.

5. We can supply stainless steel installation fastener to satisfy our customer’s requirements.

6. Please indicate clearly the type,quantity and material when you purchase installation fastener.

Q: Are you a manufacture?

A: Yes, we have specialized in this field for more than 15 years.

Q:How do you look at your customers?

A:They are not only our customers, but also our partners, we will work together to develop, win-win cooperation.

Q:Do you sell products only?

A:We not only sell products, we also provide services, we have a comprehensive after-sales service system.

Q: Do you provide sample?

A: The samples are provided free, but the customer need to pay the postage.

After the customer place order, we will deduct the postage from the payment.

Q: How long would it take to produce a sample?

A: 3-5 days after receiving the postage or get the postage collect account.

Q: What information should i provide,if i want a lowest quotation?

A: The specification of products, such as size, color, package and quantity.

Q: What is the MOQ? How many sets can fit in one Container?

A: Minimum order quantity can be discussed. We calculate the number of products that a container can hold based on the data

Q: Do u know the deliver charge to my port or my country?

A: Yes, I have ship agent, will offer u the best vessel and charge.